AQL – (Acceptable Quality Level) quality control concept.

IT refers to the minimum level of faults that are acceptable in a sample of a manufactured product.

For an entire batch to be accepted, the number of faults needs to be lower than the AQL. If it is higher, the entire batch is rejected.

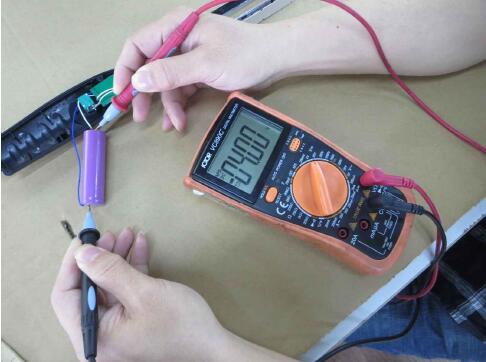

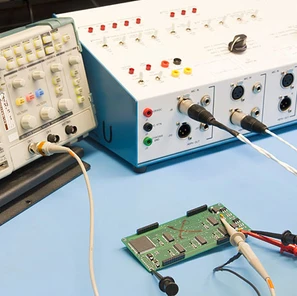

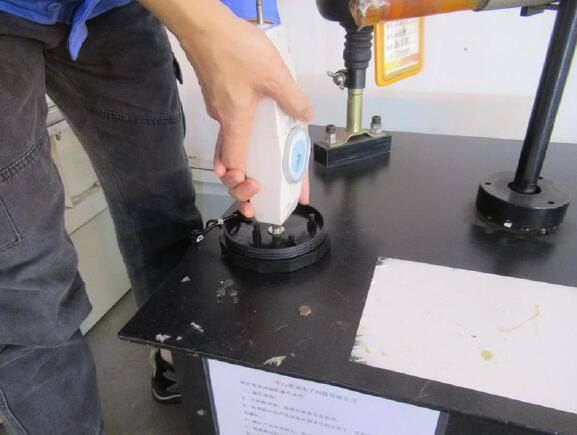

We carry out quality control during and after production by our in-house QC team.

We combine in-factory control with global laboratory tests to achieve compliance with the strictest EU regulations.

You can learn more about our process here

Today — an integrated, sustainable, quality management program with clearly focused networks is a decisive competitive advantage. At Tiroflx, we conceive your quality requirements to precisely match your business processes and offer you comprehensive support — ranging from the creation of a zero-defects culture to the development of a value-added orientation. Here, Tiroflx’s experienced experts always examine which quality methods are most efficient for your particular product and how requirements can be optimally applied to your needs.

Tiroflx quality control method

-Pass.jpg)