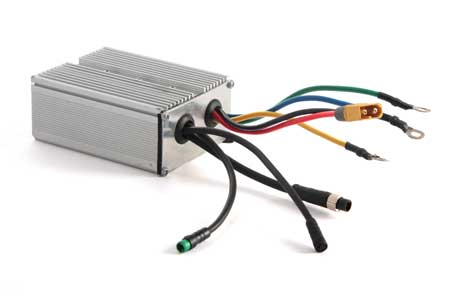

Inokim ox controller upgrade

Scooter parts for compatible Inokim

The e-scooter is a new mode of transportation that is increasingly popular. People use it to commute and travel short distances, which they cannot do by walking or biking. E-scooters use by people who have limited mobility or are disabled.

Many parts make up an e-scooter, such as the frame, wheels, brakes, and controllers.

The scooter controller is a device installed on the scooter to control the speed and direction of the scooter.

This device is usually on the scooter’s handlebar, and both hands can use it. The user will operate it by pressing buttons or switches, usually in an ergonomic position.

Jager scooter parts (Click to buy our Alibaba)

Jager scooter controller accessories 12MOS specifications

Item: value Place of Origin: Jiangsu, China

Brand Name: Jager

Model Number: JAGER OX/OXO CONTROLLER 12MOS

Power: 201-500w

Voltage: 48-60V

Charging Time: 2.5-5 Hours

Foldable: NO Range Per Charge: 30-40km

Max Speed: 50-65Km/h, 25-30km/h

Category: E-Wheel Scooter

Innovative Type: Sensor, Bluetooth, Electronic, Digital Battery Capacity: 20Ah

See our technical guide to how the scooter parts install.

Scooter controllers control the power flow between the battery and the motor, which determines the scooter’s performance. To find out how this unassuming component keeps you moving, keep reading.

Electric scooter controllers: What are they?

An electric scooter’s or electronic speed controller (ESC) controls the motor’s speed. Input from the throttle controls the current flow from the battery to the engine. For most scooters, the controller also provides regenerative braking capabilities.

Current (measured in amps) and voltage (measured in volts) use rate controllers; higher-current, higher-voltage controllers can drive scooters with more power.

Regenerative braking (or electronic braking) controllers can also route power back from the motor into the battery when activated. This feature is available on almost all controllers. As the energy dissipates by storing it back in the storm, this feature only works when the battery not fully charge. It is impossible to keep more power in a fully charged battery.

Electric scooters typically have a single controller that controls a single motor, and dual-motor electric scooters usually share the same throttle input between two engines.

Exactly how do they work?

Motor controllers consist of a programmable microcontroller that receives input signals (throttle, brake, and motor speed sensors), connects to a battery, and outputs data.

As the brain of the ESC, the microcontroller/processor is a small computer that runs a control program. ESCs listen to various signals and determine the appropriate output and timing signals. An ESC responds to the throttle signal by setting the motor’s speed (revolutions per minute) to a specific value. Sensing back-EMF from the electric motor, ESC modulates the motor signal to achieve the rate “requested” by the throttle.

User-flashable controller firmware allows over-the-air updates via Bluetooth on some scooters. Initially, this was to allow scooter manufacturers to push updates via their apps. Intrepid enthusiasts have developed tools to roll your firmware and flash it quickly. Generally, these firmware hacks increase power, top speed, and overall performance at the cost of range and scooter longevity.

Despite being a relatively fragile, low-power component, the processor cannot directly drive the motors. A network of field-effect transistors (FETs) drives the engine with a relatively weak signal. From the battery to the motor, FETs control the flow of current.

As they use, FETs generate significant heat because they are not perfectly efficient. On the controller board, they are usually by large capacitors and are often thermally attached to a heatsink or metallic case. The robustness of the FETs and thermal dissipation capability often determines a controller’s maximum sustained power.

With a high-frequency signal, the controller’s processor controls the motor’s speed by switching the on and off the FETs. This high-frequency switching causes the characteristic whine of an electric motor. A controller can control the speed of an engine by varying the duty cycle or the amount of time that the FETs are in the “on” or “off” states.

As well as modulating the duty cycle of power delivered, the processor also precisely controls its timing. Due to the way brushless DC motors work, this is necessary. A permanent magnet rotor rotates relative to a fixed electromagnet rotor. Electric scooter motors typically have 20 to 40 individual electromagnets. Just like cylinders in a car, these poles must activate with precise timing depending on the motor’s speed. Sensors measure the motor’s speed, allowing the processor to vary the frequency at which electromagnetic poles start.

What is the procedure for resetting the controller on my electric scooter?

The reset button on your speed controller can be pressed down and held to reset it in case of an electronic malfunction, such as overloading.

What is the best way to test an electric scooter controller?

Connect a multimeter to the controller of the e-scooter and turn it on. The throttle power of the controller should test, and the output should check. An output voltage of 4.3-5 volts is required for the controller to work correctly. Some parts need fixing, like the fuse, fuse holder, battery pack, wires, and connectors.